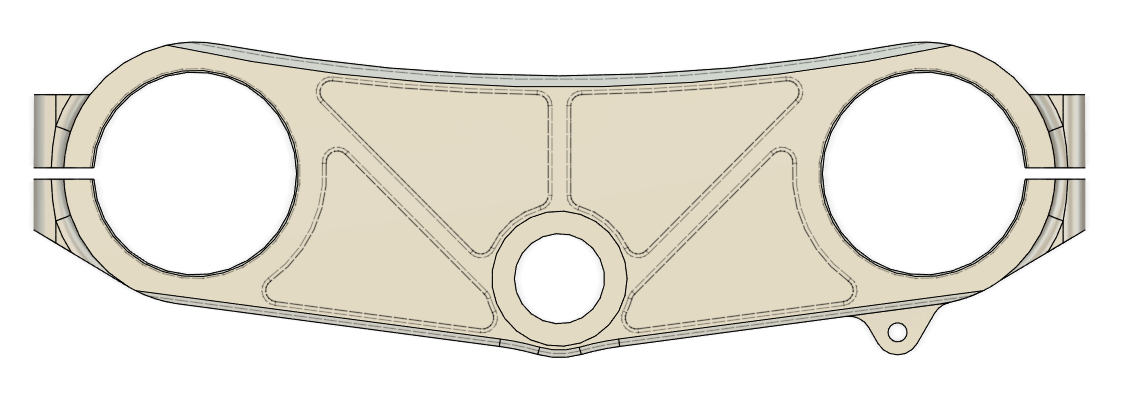

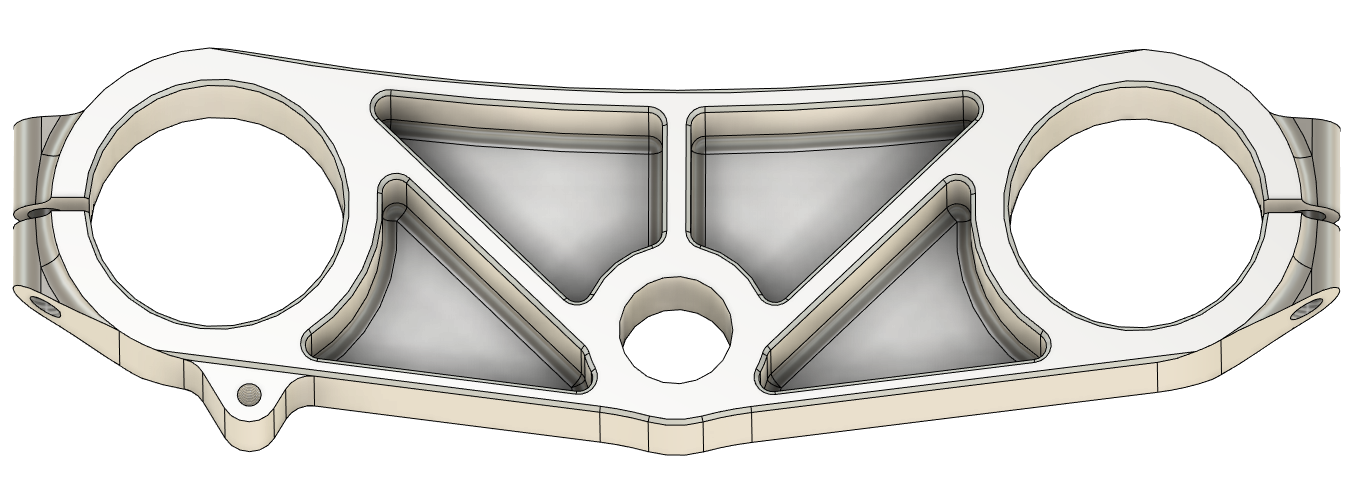

The goal of this project was to test my new CNC capabilities and apply design for manufacturing principles. The geometries (radii, chamfers, clearances and their accessibility) were all created with the machine capability and available tooling in mind. This part will use simple work holding in a two-sided operation with considerations made for an accurate and robust fixturing method.

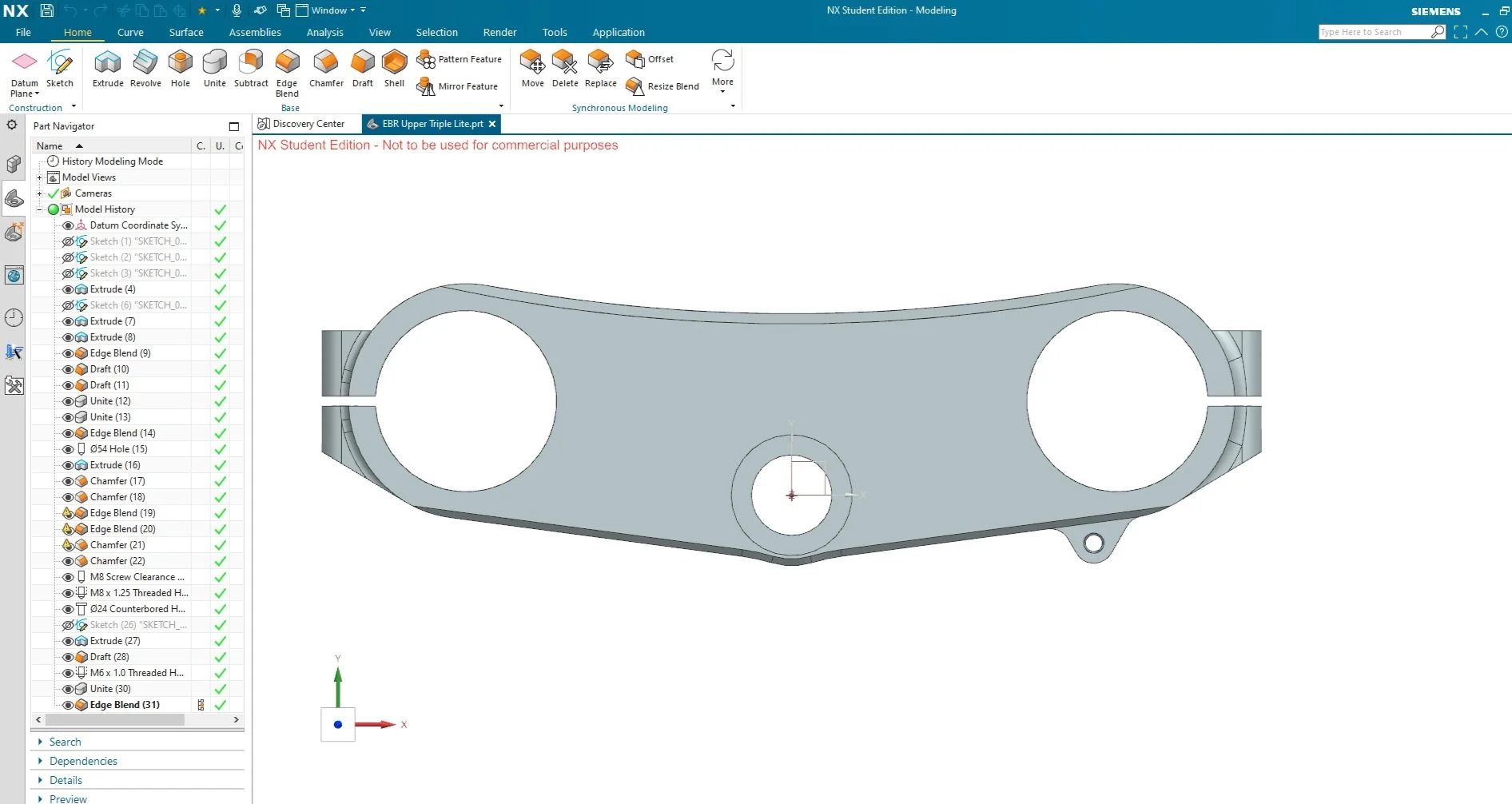

The triple tree or triple clamp of a motorcycle serves to connect the front suspension to the frame and is the steering interface. The triple tree assembly consists of 3 primary components, the upper triple, lower triple, and steering stem as well as two roller or ball bearing interfaces at the top and bottom of the frame steerer tube which gives a degree of freedom in rotation. Most commonly produced in an aluminum alloy, the top and bottom triples can be manufactured by casting, forging, or machining from billet.

The application for this upper triple clamp is for a 2014 EBR 1190SX motorcycle which I purchased in early 2017. This motorcycle was originally designed for street use and component selection was made to provide comfortable, upright ergonomics. This included a long, tall handlebar that is clamped to the upper triple tree. Since then, I converted the bike to primarily track duty and the original handlebar was scrapped for lower, “clip-on” controls. However, that eyesore of an upper triple remained. While EBR produced a track going variant of the same motorcycle, including a pleasant and streamline looking upper triple that is a direct swap. It seemed more fun to make my design and produce my own.

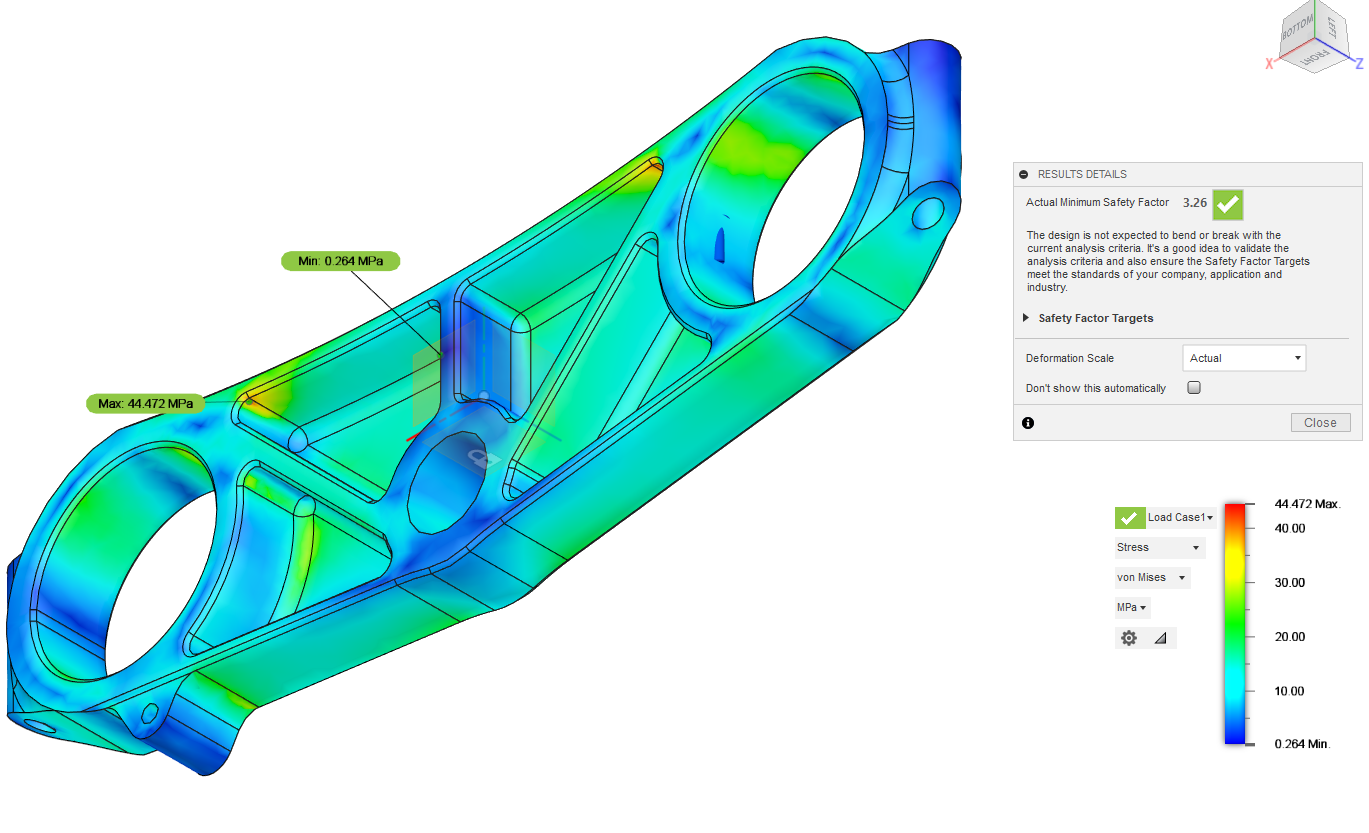

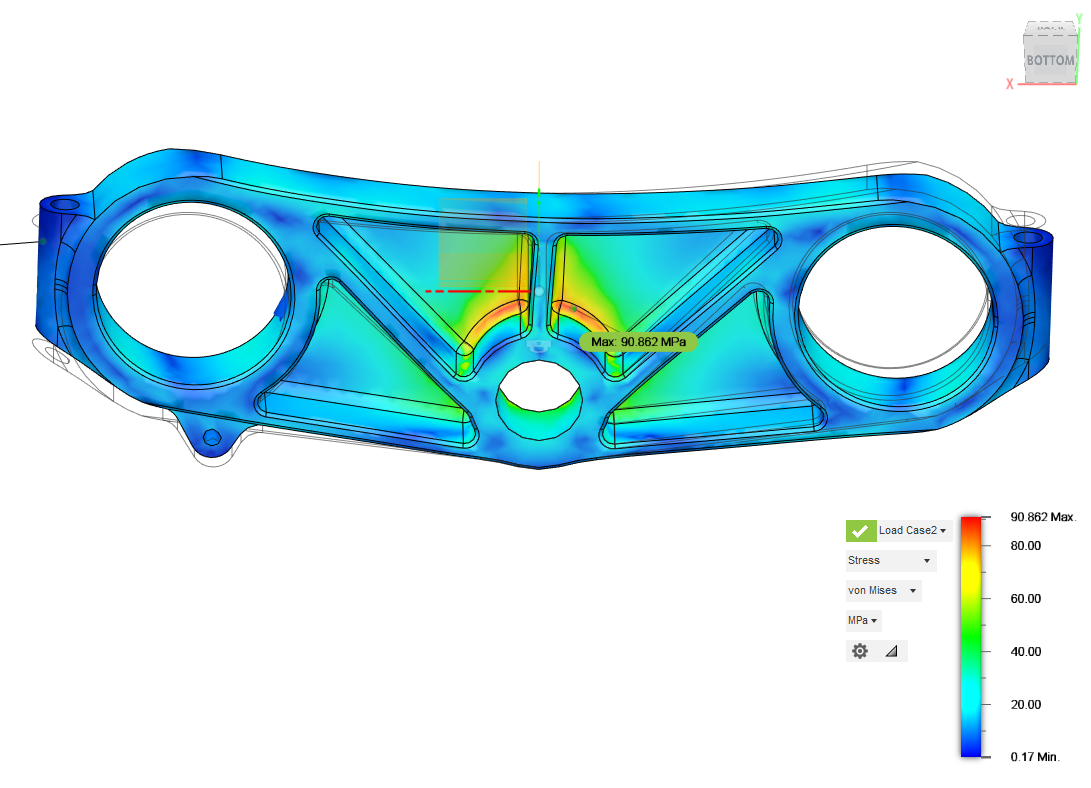

The part was designed in both NX and Fusion360 as a CAD/CAM exercise to compare the two software’s capabilities and strength simulations conducted. Several candidate materials were considered, including 2024-T351 and 6061-T6, before 7075-T7351 was selected. This was in part to it’s high fatigue resistance, strength, and good machinability but primarily driven by an excellent discount by an overstocked metal supplier.

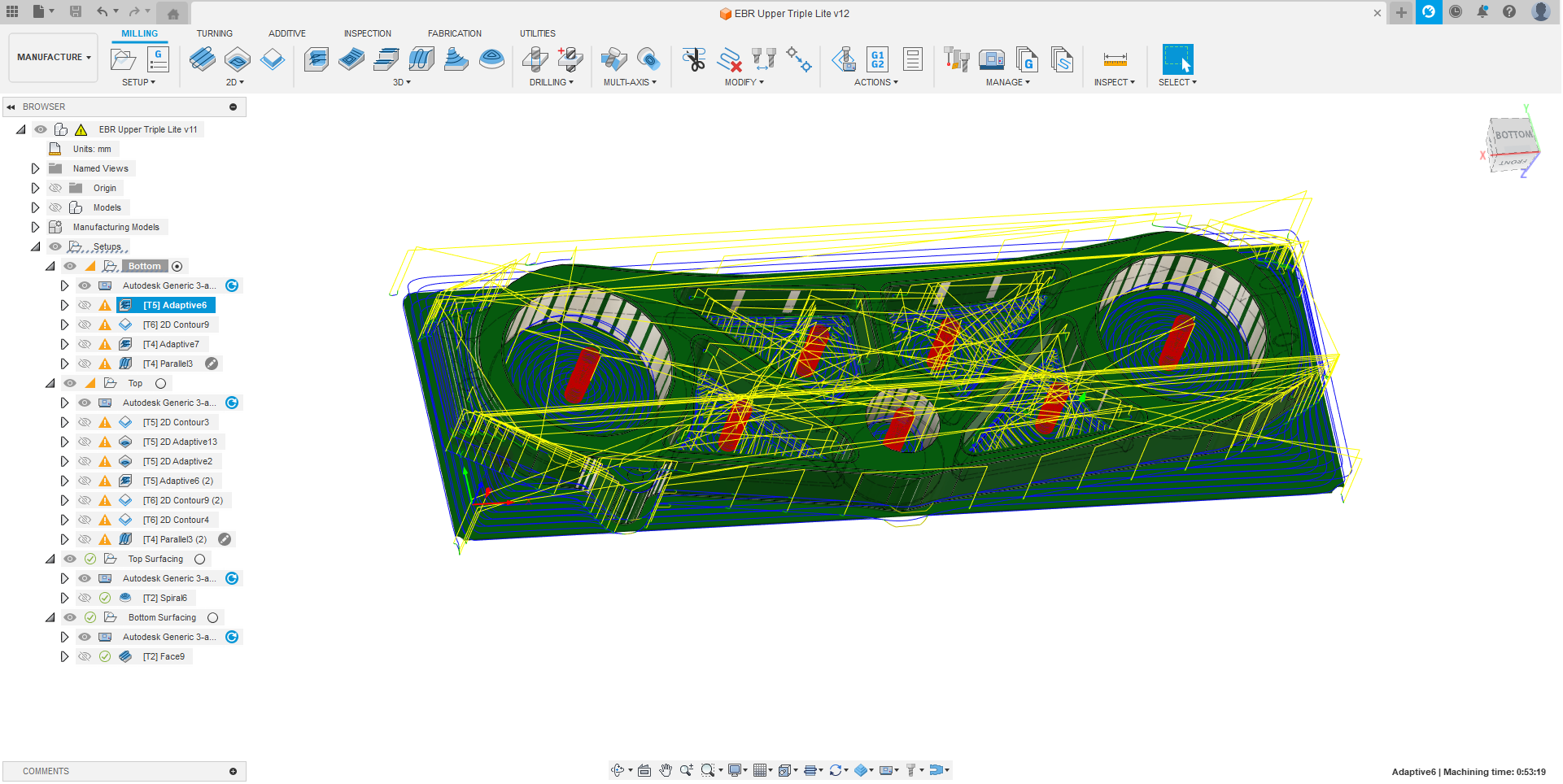

Due to the limitations of my personal CNC router (see my MPCNC project) and CNC routers in general vs. mill, special considerations were made to maximize the capabilities. Due to the lower spindle power and rigidity or my set up, end mill selection becomes critical. O-flute end mills allow for greater feed per tooth while reducing gantry stress and end mill diameter was limited a maximum of ~6mm. Adaptive/trochoidal toolpaths generated using Fusion360 CAM were utilized to reduce tool stress while maximizing MRR.